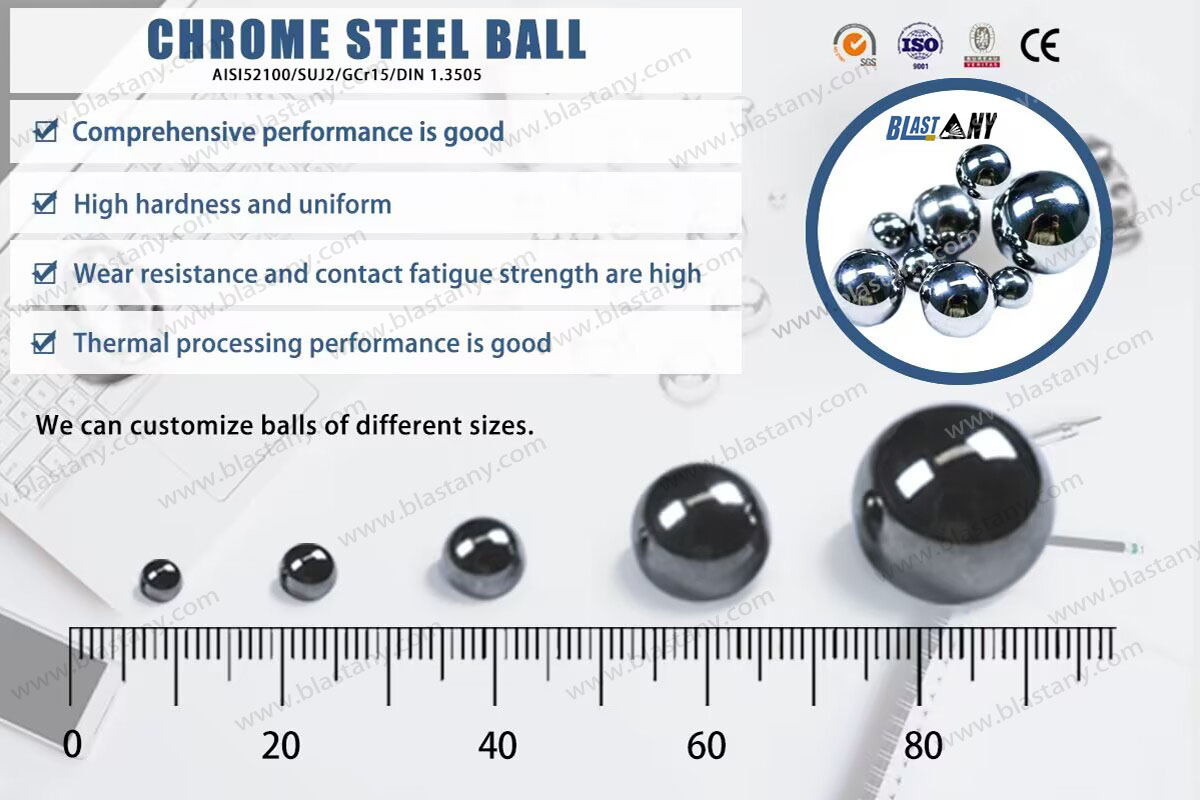

Babban ingancin AISI52100 GCr15 4mm G10-G1000 Chrome Karfe Ball don Babura / Sassan Keke / Ƙwallon Ƙarƙa

Bayanin samfur

Saboda ƙayyadaddun halaye irin su babban taurin, juriya mai girma, kyakkyawan yanayin ƙarewa da ƙarancin juzu'i, ana amfani da ƙaramin ƙarfe martensitic AISI 52100 chromium karfe don masana'antar bearings da bawuloli.

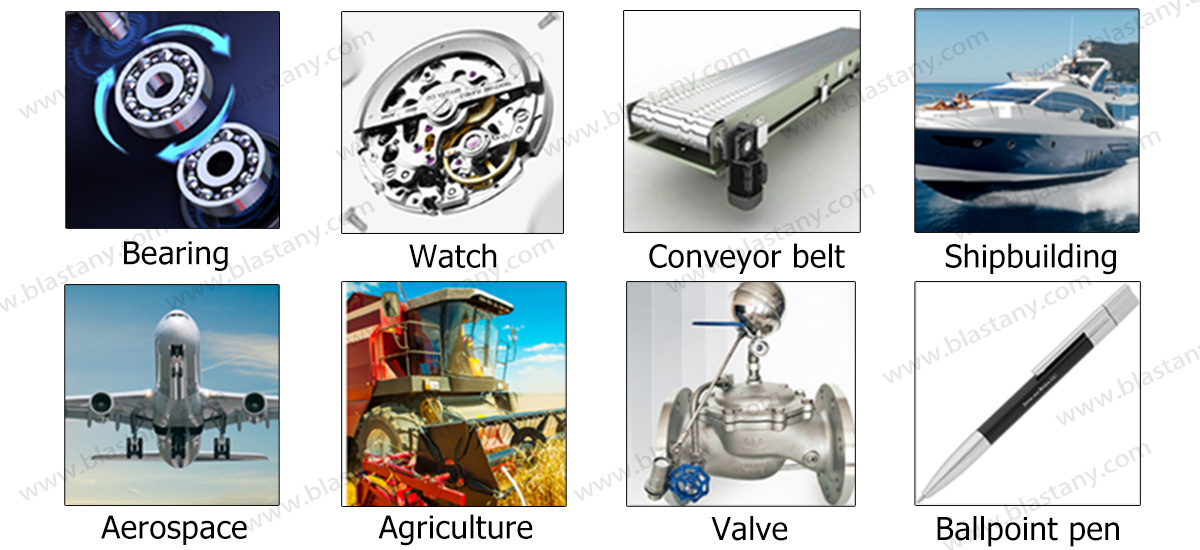

Yankunan aikace-aikace

Ƙwallon ƙafar ƙafa, Valves, masu saurin haɗawa, daidaitattun ƙwallon ƙwallon ƙafa, abubuwan abin hawa (birki, tuƙi, watsawa), kekuna, gwangwani, jagororin aljihun tebur, kayan aikin injin, hanyoyin kulle, bel ɗin ɗaukar kaya, takalmi mai nunin faifai, alƙalami, famfo, ƙafafun juyawa, kayan aunawa, sukurun ƙwallon ƙafa, kayan lantarki na gida.

jerin sigogi

| Kwallon Karfe na Chrome | |

| Kayan abu | AISI52100/SUJ2/GCr15/DIN 1.3505 |

| Girman Rage | 0.8mm-50.8mm |

| Daraja | Saukewa: G10-G1000 |

| Tauri | HRC: 60-66 |

| Siffofin | (1) Cikakken aiki yana da kyau. (2) high taurin da uniform. (3)Yin juriya da ƙarfin gajiyar lamba yana da yawa. (4) Thermal aiki yi yana da kyau. |

| Aikace-aikace | An fi amfani da ƙwallon ƙwallon chrome don kera ƙwallayen ƙarfe, rollers da bushings a kan tudu kamar injunan konewa na ciki, injinan lantarki, kayan aikin injin, tarakta, na'urorin birgima, na'urorin hakowa, motocin jirgin ƙasa da injinan ma'adinai. |

| Abubuwan sinadaran | ||||||

| 52100 | C | Si | Mn | P | S | Cr |

| 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | 0-0.025 | 0-0.020 | 1.40-1.65 | |

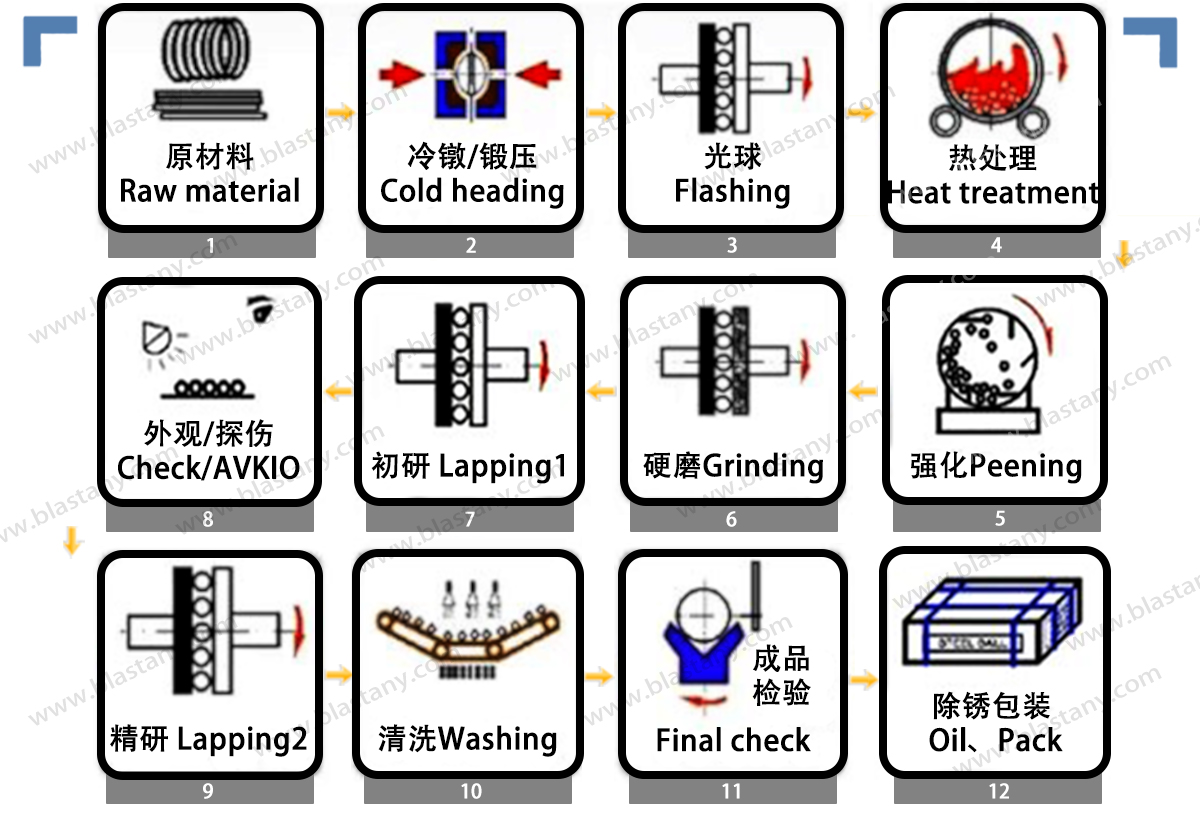

Tsarin samarwa

Raw Material Dubawa

Danyen abu yana zuwa a sigar waya. Da fari dai, masu sa ido masu inganci suna duba danyen kayan a gani don tantance ko ingancin ya kai ga alamar kuma idan akwai wasu kayan da ba su da lahani. Abu na biyu, tabbatar da diamita kuma duba takaddun shaida na albarkatun kasa.

Taken Sanyi

Injin kan sanyi yana yanke ƙayyadadden tsawon kayan waya zuwa slugs na silinda. Bayan haka, ɓangarorin ɓangarorin ɓangarorin biyu na kan kan mutu suna haifar da slug ɗin zuwa wani siffa mai kamanni. Ana yin wannan tsarin ƙirƙira a cikin ɗaki da zafin jiki kuma ana amfani da ɗan ƙaramin abu na ƙari don tabbatar da cewa rami ya cika gaba ɗaya. Ana yin taken sanyi a cikin sauri sosai, tare da matsakaicin saurin babban ball ɗaya a cikin daƙiƙa guda. Kananan ƙwalla ana kai su cikin gudun ƙwallon ƙafa biyu zuwa huɗu a cikin daƙiƙa guda.

Walƙiya

Yayin wannan tsari, abubuwan da suka wuce gona da iri da aka kafa a kusa da ƙwallon za su rabu. Ana wuce ƙwallan sau biyu a tsakanin faranti biyu na simintin ƙarfe na ƙarfe suna cire ƙananan adadin abubuwan da suka wuce gona da iri yayin da suke mirgina.

Maganin Zafi

Sa'an nan ya kamata a kula da sassan da zafi ta hanyar amfani da quenching da tempering. Ana amfani da tanderun wuta don tabbatar da cewa duk sassan suna da yanayi iri ɗaya. Bayan maganin zafi na farko, sassan suna nutsewa a cikin tafki mai. Wannan saurin sanyaya (mai kashe mai) yana samar da martensite, wani lokaci na karfe wanda ke da girman taurin kai da kaddarorin lalacewa. Ayyukan zafin jiki na gaba suna ƙara rage damuwa na ciki har sai an kai ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙarfi na bearings.

Nika

Ana yin niƙa duka kafin da kuma bayan maganin zafi. Ƙarshen Niƙa (wanda kuma aka sani da Hard Grinding) yana kawo ƙwallon kusa da buƙatunta na ƙarshe.Matsayin madaidaicin ƙwallon ƙarfeshi ne ma'auni na daidaicinsa gaba ɗaya; ƙananan lambar, mafi daidai shine ƙwallon. Matsayin ƙwallo ya ƙunshi juriya na diamita, zagaye (sphericity) da ƙaƙƙarfan yanayi wanda ake kira ƙarewar ƙasa. Ƙirƙirar ƙwallon ƙwallon ƙaƙƙarfan aiki ne. Girman Lot yana ƙayyade girman girman injinan da ake amfani da su don aikin niƙa da latsawa.

Latsawa

Lapping yana kama da niƙa amma yana da ƙarancin cire kayan abu sosai. Ana yin latsawa ta amfani da faranti guda biyu masu ƙyalƙyali da ƙaƙƙarfan slurry mai kyau kamar ƙurar lu'u-lu'u. Wannan tsari na masana'antu na ƙarshe yana inganta ƙaƙƙarfan tarkace. Ana yin latsawa ne don girman madaidaicin makin ƙwallon ƙwallon ƙafa.

Tsaftacewa

Aikin tsaftacewa sannan yana cire duk wani ruwan sarrafa ruwa da sauran kayan da ba su da kyau daga tsarin masana'anta. Abokan ciniki waɗanda ke neman ƙarin buƙatun tsaftacewa masu tsauri, kamar waɗanda ke cikin fagagen microelectronics, likitanci ko masana'antar abinci, na iya yin amfani da fa'idar Hartford Technologies ƙarin zaɓuɓɓukan tsaftacewa na zamani.

Duban gani

Bayan na farko masana'antu tsari, kowane yawa madaidaicin karfe bukukuwa sha mahara in-processing ingancin cak. Ana yin binciken gani don bincika lahani kamar tsatsa ko datti.

Roller Gauging

Roller gauging tsari ne na rarrabuwa 100% wanda ke raba ƙwallan ƙarfe na ƙasa da girman girman girman girman. Da fatan za a duba dabanbidiyo akan tsarin ma'aunin abin nadi.

Kula da inganci

Ana duba kowane ƙwallo daidai gwargwado don tabbatar da buƙatun ƙira don jurewar diamita, zagaye da ƙaƙƙarfan saman. A yayin wannan tsari, ana kimanta wasu halaye masu dacewa kamar taurin, da duk wani buƙatun gani kuma ana kimanta su.

Rukunin samfuran