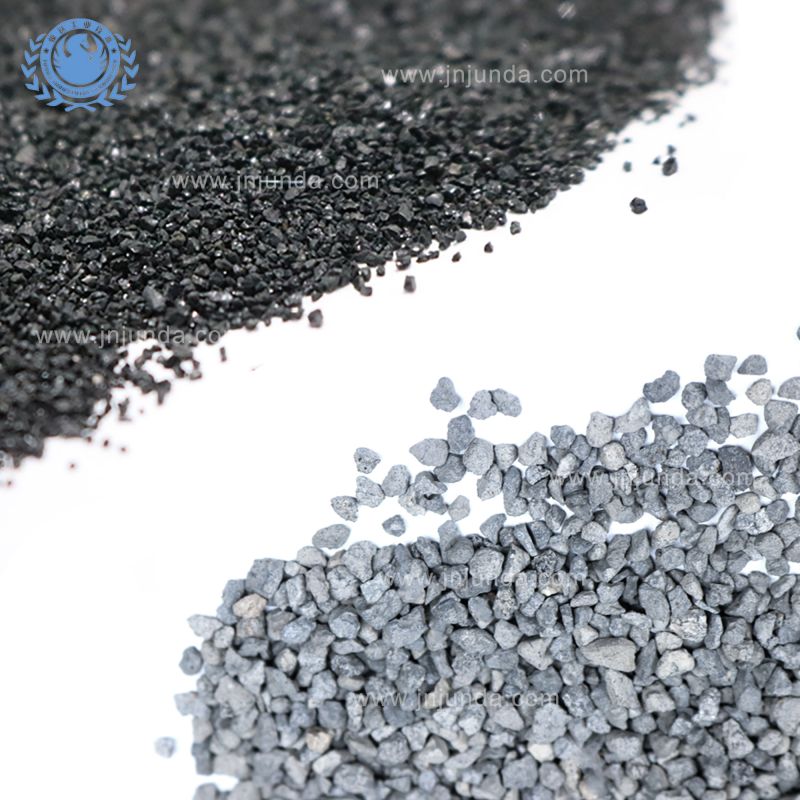

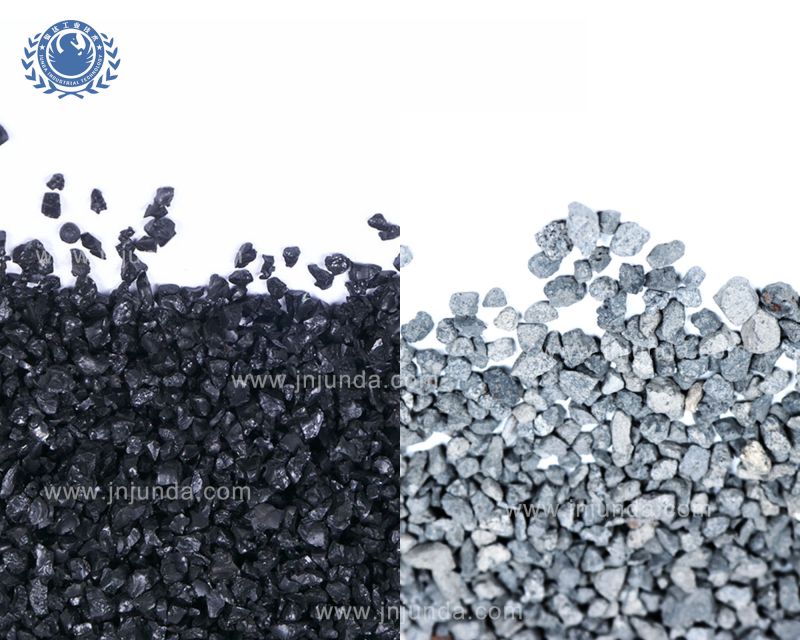

Slag ya samar bayan murhun karfe yana narkewa kuma an fitar dashi, kuma ana kiranta da slag. Ana sarrafa slag ta hanyar murƙushe da kuma allon gwargwadon amfani da buƙatu daban-daban, kuma ana bayyana bayanai ta hanyar lambar raga ko girman barbashi.

Slag slag yana da ƙarfi, siffar da lu'ulu'u, ƙaramin ƙura a cikin sandblasting, saboda ana iya sake yin amfani da shiD, fa'idodin tattalin arziki shima suna da matukar kyau, shekaru 10, shuka gyara, jigilar baƙin ƙarfe ana amfani da jan karfe na dutse kamar yadda cire tsatsa.

Lokacin da ake buƙatar zane mai sauri da ingantaccen feshin, slag slagshine mafi kyawun zabi.

Karfe slag tsari tsari ne saboda rabuwaabubuwa daban-daban daga slag. Ya ƙunshi aiwatar da rabuwa, murƙushewa, zagaye, rarrabuwa, da iska rabuwa da Slag da aka samu a lokacin smleting tsari. Baƙin ƙarfe, silicon, aluminium, aluminum, da sauran abubuwan da ke ciki suna rarrabe, an sarrafa su sosai suna amfani da amfani da albarkatun.

A farfajiya ta gama aiki bayan slag magani shine sama da matakin SA2.5, kuma farfajiya yana sama da buƙatun haɗin masana'antar masana'antu. A lokaci guda, farfajiya na farfajiya da ƙarfin aiki na aikin suna da alaƙa da girman ƙwayar ƙarfe da ƙaruwa tare da karuwar girman barbashi. Karfe slag yana da wasu juriya na murƙushewad za a iya sake amfani dashi.

Bambanci:

1.Berpering farfajiya na sama na samfuroriTed tare da kayan nika daban-daban, an gano cewa an bi da farfajiyar aikin da ƙarfe na ƙarfe yana da haske fiye da na ƙarfe.

2.Wanda aka bi da kayan aikin da aka bi da Withadden slag fiye da na karfe slag, akasin ga dalilai masu zuwa, slagles yana da ƙarfi fiye da na karfe slag, wanda ya fi sauƙi don inganta ƙarfin aiki

Lokacin Post: Mar-21-2024