10MM TO 130MM Simintin Niƙa Media Karfe Ball don Ma'adinan Ƙarfe na Ball Mill da Shukan Siminti

Bayanin samfur

Tsarin samarwa

Ƙwallon simintin, wanda kuma ake kira ƙwallo mai niƙa, ana yin ta ne daga tarkacen karfe, tarkace, da sauran kayan da aka zubar. Abubuwan da aka ambata a sama suna narkar da su sosai kuma suna gudanar da ci gaba mai gudana bayan an mai zafi. A lokacin da ake narkewa, ana fara ƙara adadin ƙarfe da yawa kamar vanadium, baƙin ƙarfe da manganese a cikin hayaƙin hayaƙin don samun amfanin da ake so da ƙayyadaddun amfanin. Wadannan abubuwa za su iya zubar da ƙarfen da ya fi narkakkarwa a cikin samfurin layin samar da masana'antar ƙarfe.

Aikace-aikace

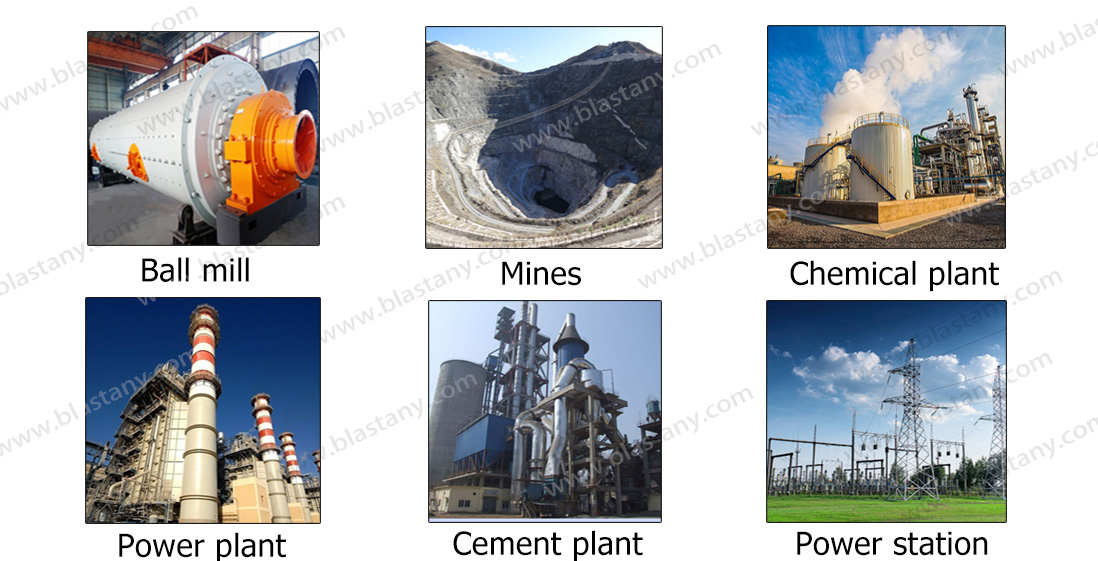

Za a iya amfani da ƙwallon Ƙarfe don yin amfani da shi sosai a aikace-aikace daban-daban, gami da

Kamfanin yashi na Silica/Tsarin Siminti/Tsarin Kemikal/Tsarin wutar lantarki/Ma’adanai/Tashar wutar lantarki

/Kamfanonin sinadarai/Niƙan niƙa/Mashin ƙwallon ƙwallon ƙafa/Masana'antar kwal

Gabatarwa na simintin gyare-gyaren kayan ƙwallon ƙarfe

Kwallan simintin ƙarfe na Chrome sune ƙwallayen niƙa na simintin watsa labarai waɗanda ke ɗauke da ƙayyadaddun kaso na chromium, kuma ta inda aka raba su zuwa manyan ƙwallayen simintin ƙarfe na chromium, matsakaicin ƙwallan ƙarfe na chromium simintin ƙarfe da ƙananan ƙwallan simintin ƙarfe na chromium. An raba ƙwallayen simintin ƙarfe na chromium zuwa Manyan Kwallan Cast Karfe na Chromium, Matsakaicin Ƙwallon Ƙarfe na Chromium da Ƙwallon Ƙarfe na Chromium Cast. Tare da fasalin babban taurin, ƙarancin lalacewa, da ƙarancin karyewa, ƙwallayen niƙa na simintin ƙarfe galibi ana amfani da su a masana'antar siminti, masana'antar ma'adinai, masana'antar ƙarfe, masana'antar samar da wutar lantarki da masana'antar gini.

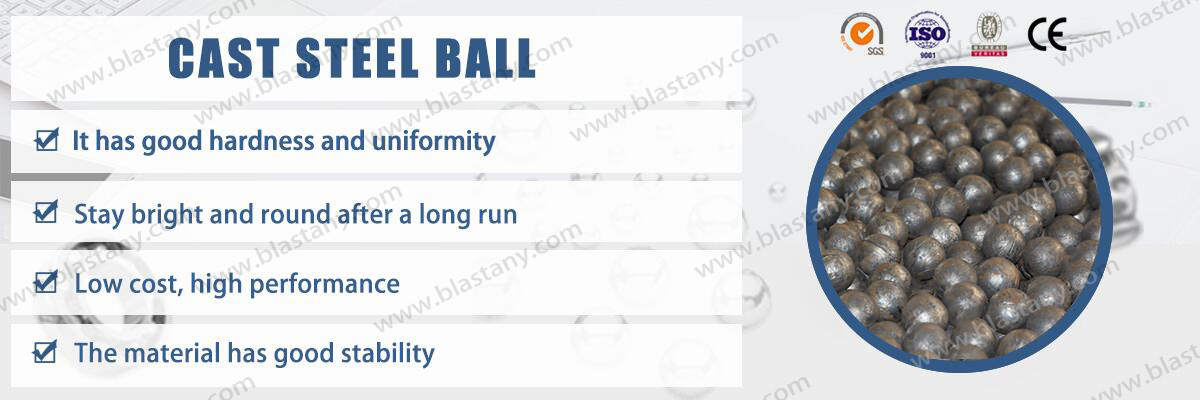

Siffofin Kwallon Niƙa Karfe

1, The raw kayan ne duk hali karfe scraps, wanda ya ƙunshi jan karfe, molybdenum, nickel da sauran daraja karfe abubuwa, wanda zai iya yadda ya kamata inganta matrix tsarin na karfe ball.

2, Our kayayyakin da ake samar da matsakaici mita lantarki makera wanda zai iya yadda ya kamata tabbatar da kwanciyar hankali na abu. Kwallaye ba su da sauƙin kwaɓe da nakasu yayin amfani. Ko da zai iya ci gaba da haske da zagaye bayan dogon lokaci yana gudana.

3, Mafi ci-gaba manyan-sikelin atomatik man quenching samar line aka soma ga zafi magani, wanda tabbatar da kyau taurin da uniformity na kayayyakin.

Hanyoyi guda uku don yin ƙwallon karfe

1. Hanyoyi uku na masana'antar ƙwallon karfe

Akwai matakai iri uku na ƙirar ƙwallon ƙarfe: simintin gyare-gyare, ƙirƙira, da mirgina.

(1) Simintin gyare-gyare: Ingantattun ƙwallan ƙarfe na ƙarfe ya dogara da abun ciki na chromium. A cikin 'yan shekarun nan, hauhawar farashin chromium, kariyar muhalli, da sauran abubuwa sun haifar da haɓakar farashin simintin ƙarfe.

(2) Kirkira: Yin amfani da babban ƙarfe na manganese azaman albarkatun ƙasa, ana amfani da hammata masu ƙirƙira pneumatic da ƙwallon ƙwallon don yin ƙwallon ƙarfe. Ƙwayoyin ƙarfe da aka ƙirƙira suna da ma'ana mai ma'ana na babban-carbon, manganese, chromium, da sauran abubuwan gami, kuma suna da ƙarfi mai ƙarfi a cikin samar da maganin zafi, ƙaramin bambanci a cikin tauri tsakanin ciki da waje, da bambancin ƙimar tasiri, wanda ke sa ƙwallan ƙirƙira ƙarfi fiye da jefa kwallaye.

(3) Mirgina: Yin amfani da manyan sandunan ƙarfe na manganese azaman kayan albarkatun ƙasa, ƙwallan ƙarfe ana yin su ta hanyar injin mirgina tare da rollers karkace.

| Abu | Haɗin Sinadari(%) | |||||||||

| C | Si | Mn | Cr | P | S | Mo | Cu | Ni | ||

| High chrome jefa gri nding bukukuwa | ZQCr12 | 2.0-3.0 | 0.3-1.2 | 0.2-1.0 | 11-13 | ≤0.10 | ≤0.10 | 0-1.0 | 0-1.0 | 0-1.5 |

| ZQCr15 | 2.0-3.0 | 0.3-1.2 | 0.2-1.0 | 14-17 | ≤0.10 | ≤0.10 | 0-1.0 | 0-1.0 | 0-1.5 | |

| ZQCr20 | 2.0-2.8 | 0.3-1.0 | 0.2-1.0 | 18-22 | ≤0.10 | ≤0.08 | 0-2.0 | 0-1.0 | 0-1.5 | |

| ZQCr26 | 2.0-2.8 | 0.3-1.0 | 0.2-1.0 | 22-28 | ≤0.10 | ≤0.08 | 0-2.5 | 0-2.0 | 0-1.5 | |

| Tsakiyar chrome simintin niƙa bal ls | ZQCr7 | 2.0-3.2 | 0.3-1.5 | 0.2-1.0 | 6.0-10 | ≤0.10 | ≤0.08 | 0-1.0 | 0-0.8 | 0-1.5 |

| Ƙananan ƙwallan simintin gyare-gyare na chrome | ZQCr2 | 2.0-3.6 | 0.3-1.5 | 0.2-1.0 | 1.0-3.0 | ≤0.10 | ≤0.08 | 0-1.0 | 0-0.8 | |

Babban simintin simintin chromium (Maɗaukakin Ƙwallon Ƙwallon Ƙwallon Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙwararrun Ƙwararru na Chrome)

| Diamita mara kyau | Nauyin ball guda a matsakaici (g) | Yawan / MT | Surface-hardness(HRC) | Gwajin tasirin haƙuri (Lokaci) |

| φ15 | 13.8 | 72549 | >60 | > 10000 |

| φ17 | 20.1 | 49838 | > 10000 | |

| φ20 | 32.7 | 30607 | > 10000 | |

| φ25 | 64 | 15671 | > 10000 | |

| φ30 | 110 | 9069 | > 10000 | |

| φ40 | 261 | 3826 | > 10000 | |

| φ 50 | 510 | 1959 | > 10000 | |

| φ60 | 882 | 1134 | > 10000 | |

| φ70 | 1401 | 714 | > 10000 | |

| φ80 | 2091 | 478 | >58 | > 10000 |

| φ90 | 2977 | 336 | > 10000 | |

| φ100 | 4084 | 245 | > 8000 | |

| φ120 | 7057 | 142 | > 8000 | |

| φ130 | 8740 | 115 | > 8000 |

Rukunin samfuran